Commitment to Providing Quality Plastic Bottle and Jar Packaging Solution111

When manufacturing our plastic bottles and jars, we consider all the production measures to ensure the highest quality. Gracepack uses new technology and investment processes to ensure quality assurance. We also established mutual AQLs with our customers.222

Our Design Center in China

We have a knowledgeable and expert team of engineers and designers with a commitment to bringing quality to all our clients. Our engineering and designing team fully utilizes all the advanced tools for customizing plastic bottles and jars for packaging applications. Through our collaborative center, we can help our clients face-to-face and talk about the design.

Along with our design center, we also have engineering resources as well as an innovation lab that allows having capabilities in providing new ideas. It is also where we developed design concepts and samples.

Gracepack Innovation Lab

Improving the quality of our products is an essential part of our manufacturing processes. Therefore, we have integrated our factory with an innovation lab to provide the following advantages:

- Innovation lab with a variety of departments working together as a team

- Our innovation lab is where we create newly developed products

- Producing high-performing products that are faster to market222

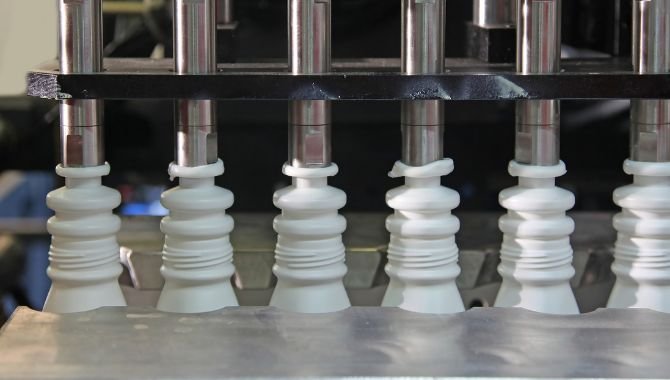

Quality Manufacturing and Processing

-

Raw materials that are FDA approved

Complied to different specifications through rigid manufacturing

Documented training programs to monitor quality procedures

Well-maintained, high-tech, and efficient equipment

First piece approval and in-process inspection

Fully Certified Production Process

At Gracepack, we make sure to comply different international standards for quality and safety including:

- ISO22000 Certificate

- BPA Free Certificate

- ISO9001 Certificate

- SABER Factory Audit Certificate

- FDA Approved

- ISO Standards Certified